The

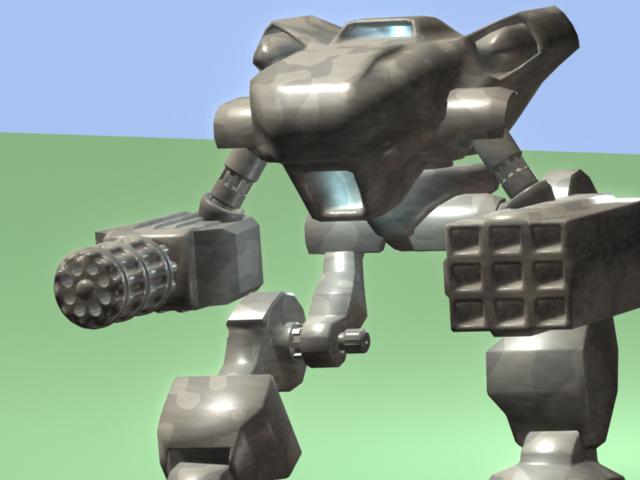

mech was boned and skinned in the usual fashion.IK

handles were added to its feet to control its leg, and also to its arms.IK

handles were also added to each of its foot appendages to control where

they point to.

Then

I used Maya?s expressions to control the various joints of the mech.I

used one expression for each of the foot?s appendages so that they would

always point downward when it raised its foot, to simulate the force of

gravity.This couldn?t be done with

simple parenting, because I wanted the IK handle of the appendage to be

parented to the movement of the whole foot, but only in terms of its X

and Z coordinates.I wanted the IK

handle?s Y coordinate to always be 0 so the foot appendage would always

be pointing at the floor.But since

all the appendages were grouped as a ?foot? node, all the IK handle?s translation

attributes are always 0, since it is the group that is moved when moving

the leg.Many methods of grouping

and parenting were attempted, but none worked.So

to make each foot appendage point to the ground, I wrote an expression

to assign to the Y coordinate the negative value of the group?s Y coordinate;

this way, they would cancel each other out and the IK handle will always

effectively be at Y = 0.

//controls

right foot appendages

ik_right_toe.translateY

= -rfootc.translateY;

ik_right_ball.translateY

= -rfootc.translateY / 2;

ik_right_heel.translateY

= -rfootc.translateY;

ik_right_wing_left.translateY

= -rfootc.translateY;

ik_right_wing_right.translateY

= -rfootc.translateY;

//controls

left foot appendages

ik_left_toe.translateY

= -lfootc.translateY;

ik_left_ball.translateY

= -lfootc.translateY / 2;

ik_left_heel.translateY

= -lfootc.translateY;

ik_left_wing_left.translateY

= -lfootc.translateY;

ik_left_wing_right.translateY

= -lfootc.translateY;

Next,

I wanted to automate the secondary animation of the mech so that its various

parts would bounce accordingly along its walk cycle.I

added custom attributes for the torso?s up and down bounce and tilt, its

side to side bounce tilt, and its forward and backward shifting.I

also added attributes for its arms bouncing, its legs lifting and forward

and backward movement.I then used

expressions to link all of these to a ?Walk_Cycle? attribute, so that when

I slid this attribute, the mech would walk in place.I

also added custom attributes ?Stride_Length,? which affects how big the

mech?s stride is, and ?Speed? which just affects the apparent bounciness

of the mech (not the distance covered).Stride_Length

was also rigged to control the bounciness of the torso and arms, because

a larger stride should effect more secondary motion.The

Speed control made the mech much bouncier at higher speeds.Also,

since the motions of the legs at a slow walk and a full run are vastly

different (when running, there are times when both feet are in the air,

which is not the case when walking), two different motion curves were created

at each extreme, and interpolated between using the Speed attribute.Expressions

were the mechanism by which I linked the two different animation curves

and the Speed and Stride_Length attribute to the Walk_Cycle attribute,

which was linked to the actual IK handles using the Set Driven Key tool

in Maya.

mech_control.RFStride_h

= ((mech_control.Speed / 10) * mech_control.RightFootStrideRun * (mech_control.StrideLength

/ 40)) +

(((10

- mech_control.Speed) / 10) * mech_control.RightFootStride * (mech_control.StrideLength

/ 40));

//foot

lift due to stride forward

mech_control.LFL_h

= ((mech_control.Speed / 10) * mech_control.LeftFootLiftRun * (.1 + mech_control.StrideLength

/ 80) * (1 + mech_control.Speed / 10)) +

(((10

- mech_control.Speed) / 10) * mech_control.LeftFootLift * (.1 + mech_control.StrideLength

/ 80) * (1 + mech_control.Speed / 10));

mech_control.RFL_h

= ((mech_control.Speed / 10) * mech_control.RightFootLiftRun * (.1 + mech_control.StrideLength

/ 80) * (1 + mech_control.Speed / 10)) +

(((10

- mech_control.Speed) / 10) * mech_control.RightFootLift * (.1 + mech_control.StrideLength

/ 80) * (1 + mech_control.Speed / 10));

//foot

lift due to strafe left/right

$strafe_liftL

= 0;

$strafe_liftR

= 0;

.O[4]

= .I[10];

.O[5]

= .I[11];

mech_control.HRUD_h

= mech_control.HipsRaiseUD * (mech_control.StrideLength / 40) * (mech_control.Speed

/ 5) + mech_control.Speed - 1;

mech_control.HTUD_h

= mech_control.HipsTiltUD * (mech_control.StrideLength / 40) * (mech_control.Speed

/ 10);

mech_control.HLLR_h

= mech_control.HipsLeanLR * (mech_control.StrideLength / 40) * (.25 + mech_control.Speed

/ 40);

mech_control.HSLR_h

= mech_control.HipsSwayLR * (mech_control.StrideLength / 40) * (.75 + mech_control.Speed

/ 40);

mech_control.HSFB_h

= mech_control.HipsSurgeFB * (mech_control.StrideLength / 40) * (.25 +

mech_control.Speed / 20) + mech_control.Speed - 1;

mech_control.ArmBounce_h

= mech_control.ArmBounce * (mech_control.StrideLength / 40) * (mech_control.Speed

/ 10);

mech_control.HLookLR_h

= mech_control.HipsLookLR * (mech_control.StrideLength / 40) * (mech_control.Speed

/ 10);

mech_control.TLLR_h

= mech_control.TorsoLookLR;

For easy testing,

I next rigged the mech?s walk cycle to the frame number.This

was so I could just press the play button and the mech would walk/run in

place.I used an expression to relate

the frame time to the walk cycle.Using

this, the apparent speed of the mech could be easily seen.Not

only was the mech bouncier at higher speeds, it took more steps in the

same amount of time as it would?ve at lower speeds.

The next part was

rigging the mech so that its walk cycle would be automatically generated

based on its position and rotation.This

used trigonometry to figure out how much it was going forward based on

both its heading and its bearing, and then related it to the Walk_Cycle

attribute, which was looped over and over using the modulus of the distance

covered.Using this technique, there

is no footslip while the mech is walking.The

Speed and Stride_Length attributes worked well in this case too.But

the Speed now only controlled how bouncy the mech looked.It

was the distance covered by the keyframing that would control the speed

of the mech, or the number of steps it took in a certain amount of time.I

also had to incorporate reference positions and rotations, because you

just cannot measure the distance traveled from the origin, since the mech

will be rotating and such.

This approach had

a few other shortcomings.The mech?s

automatic motion only looks good when walking in a straight line.There

is no consideration of side-stepping or rotating while walking, so that

if the mech is not keyframed in a straight line, there will be lateral

footslip.I feel that, if given more

time, I could have at least implemented the side-stepping by incorporating

a Side_Step_Cycle attribute, much like the Walk_Cycle attribute.Then

I would interpolate between the two based on the differences between the

angles of its heading and its bearing.Also,

to avoid longitudinal footslip, there were constraints put on the animation

curves of the mech?s feet so that it would be linearly aligned with the

distance traveled.This causes a

slightly less than realistic motion, because I couldn?t adjust the feet?s

curves to have slow in and out tangents, because there were no tangents

for the overall motion of the mech body.

$bearing_dist

= sqrt(pow(mech_control.translateX - mech_control.RefPosX, 2)

+

pow(mech_control.translateZ - mech_control.RefPosZ, 2));

if

($bearing_dist != 0) {

$bearing_dist

*= mySign(mech_control.translateX - mech_control.RefPosX)

*

-mySign(mech_control.translateZ - mech_control.RefPosZ);

if

(mech_control.translateX - mech_control.RefPosX < 0)

$bearing_dist

= -$bearing_dist;

$bearing_angle

= acosd((mech_control.translateX - mech_control.RefPosX) / $bearing_dist);

$heading_angle

= mech_control.rotateY;

$angle_between

= $bearing_angle - $heading_angle;

$heading_dist

= $bearing_dist * cosd($angle_between);

mech_control.one_cycle

= fmod(mech_control.one_cycle + ($heading_dist * 24 / (mech_control.StrideLength

* 2)), 24);

}

mech_control.RefRotY

= mech_control.rotateY;

mech_control.RefPosX

= mech_control.translateX;

mech_control.RefPosZ

= mech_control.translateZ;

Overall, I think the

technical piece was a great success.I

had tried many alternatives to reach a certain goals, and finding the right

method out of many seemed to be the critical lesson learned.